If you’re ever dealt with unexplained system inefficiencies, sticky servo valves, or increased equipment downtime, there’s a good chance varnish is the culprit, especially in industrial equipment. This stubborn, often invisible layer of oxidation byproducts can silently sabotage even the most well-maintained lubrication systems. It’s usually only detectable with oil analysis sample testing, even though varnish can coat metal surfaces throughout industrial machinery. Once this happens, varnish build-up can restrict flow, clog filters, and severely impact equipment performance.

At Greg’s Petro, we know our industrial customers rely on the consistent performance of their heavy-duty industrial equipment. This type of machinery is expensive, and taking such critical machinery offline for repairs and maintenance can have a severe impact on a company’s production and profitability. That’s why we’re putting a spotlight on one of the most underestimated threats to system health: varnish and sludge deposits—and introducing a solution that has rescued machines others thought were beyond saving.

What is varnish, and why does it matter?

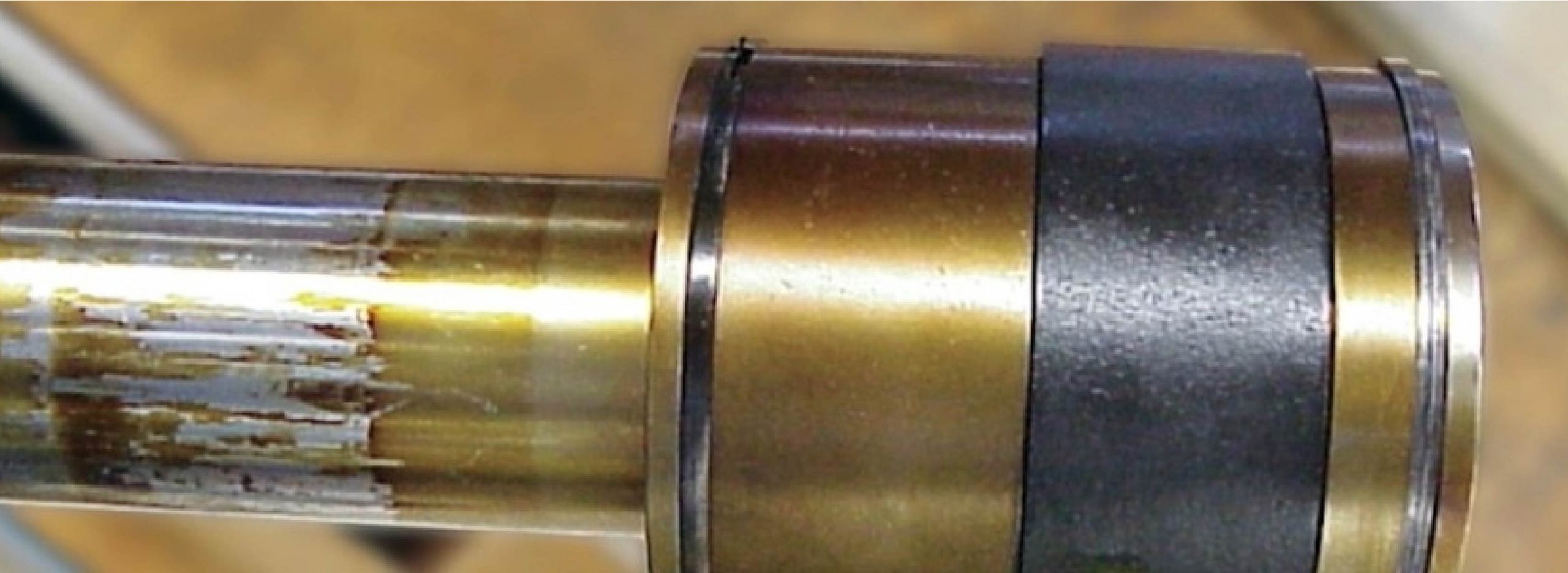

Varnish is a thin, insoluble residue that forms in high-pressure, high-heat environments. It can occur in any type of equipment but is most common in systems that use circulating oil or hydraulic fluids. It’s the result of lubricant degradation, often caused by oxidation, elevated temperatures, or system contamination.

Once the lubricant begins to break down, the degraded particles cluster together, forming sticky, magnetically charged micro-contaminants that plate onto metal surfaces. Most varnish typically occurs in tight or hard-to-reach areas of industrial equipment, such as servo valves and flow regulators. In these areas, it’s challenging to remove the varnish, or even notice it, which can cause:

- Reduced system responsiveness

- Increased wear and energy consumption

- Sluggish or erratic valve operation

- Frequent filter clogs

- Heat transfer inefficiencies

- Unexpected downtime and repair costs

Unfortunately, once varnish forms, it won’t dissolve or disappear on its own. Even manually scrubbing the varnish away doesn’t work enough to remove varnish particles, and oil changes alone aren’t enough. That’s where a dedicated system cleaner, like Chevron VARTECH ISC, can make a significant difference!

Chevron VARTECH® Industrial System Cleaner (ISC) is a non-solvent varnish removal product that works while the equipment is in operation. Simply add it directly to the hydraulic fluid or circulating oil before a scheduled oil change. It doesn’t just loosen varnish; it solubilizes it, breaking it down and suspending it in the oil so it can be safely drained with the used lubricant.

Key Benefits of VARTECH ISC:

- Dissolves varnish, removing buildup from hard-to-reach metal surfaces

- Protects system health without harming seals, metals, or oil additives

- Simplifies maintenance by eliminating the need for harsh chemical flushes or multiple oil changes

- Reduces operating temperatures by restoring optimal heat transfer efficiency

- Compatible with most oils, including mineral and synthetic lubricants

Chevron’s VARTECH ISC is highly effective, especially compared to other aggressive cleaning detergents, because it doesn’t just cause the loosened varnish to flake off and clog your system elsewhere. The particles remain stable and suspended until safely removed during the oil change.

How effective is VARTECH ISC?

The effectiveness of VARTECH ISC isn’t just theory. This product has been tested in real-world, high-stakes scenarios and has proven its effectiveness. One Chevron customer, operating a plastic injection molding facility, faced an unthinkable prospect: the potential scrapping of three Cincinnati Milacron 850-ton machines, each valued at approximately $500,000. These hydraulic units had become severely clogged with varnish, resulting in unreliable performance and production losses.

After trying two different commercial cleaning agents, plus mechanical scrubbing, with no success, the machines were all but written off. That’s when they turned to VARTECH ISC for a final attempt. Chevron’s field engineers recommended a VARTECH ISC treatment just before an oil change. The product was circulated through the system under normal operating conditions, gradually breaking down and solubilizing the varnish from internal components. The result?

“Not only was the varnish completely removed, leaving the affected components with a ‘like-new’ shine, but equipment thought to be at the end of its life was able to go back into full operation—saving the customer an estimated $1.5 million.”

After treatment, the machines resumed production at normal rates. The company was able to avoid expensive equipment downtime and didn’t need to replace the machinery. It was all thanks to Chevron’s VARTECH ISC, and they now had an effective solution for future varnish removal needs.

How does Chevron’s VARTECH ISC work?

Using Chevron VARTECH ISC is easy. Simply add this product to your regular oil maintenance schedule and follow the steps below.

- Add to the system at 5–10% concentration (depending on severity)

- Circulate during normal operations for 7–30 days

- Drain the warm oil and varnish-laden particles at the next scheduled oil change

- Clean the reservoir (if possible), replace filters

- Refill with fresh Chevron-approved oil

Once this process is complete, you’ll end up with a varnish-free system and a clean slate for testing new lubricants and avoiding equipment shutdowns.

When to consider system cleaning

You should consider a cleaning with VARTECH ISC if you notice:

- Servo valve delays

- Inconsistent pressure or temperature readings

- Recurring filter plugging

- Discolored or cloudy oil

- Signs of system overheating

- Component erratic behavior or failure

Even if varnish isn’t visible to the naked eye, oil analysis methods like Membrane Patch Colorimetry (MPC) or Chevron’s MPC Plus testing can indicate the early presence of varnish precursors. Regular testing can help you catch the warning signs of a varnish problem before it begins, so you’ll know if a system cleaning is needed.

Don’t wait for equipment failure

Industrial equipment is expensive to replace and to shut down for maintenance issues. Implementing regular system cleaning using VARTECH ISC can help you avoid these issues and extend the life of your equipment. Even though varnish can be a silent killer in your hydraulic or turbine system, it doesn’t have to be. Chevron VARTECH ISC is a field-proven tool that restores performance, extends the life of your equipment, and protects your investment. We even have diesel supply service, delivery fuel to you…when, and where you need it. So if you’re ready to bring your equipment back to like-new condition and avoid costly repairs, contact Greg’s Petro today to order VARTECH ISC!